Our engineer can designprocessing and made all kinds of extruder screen pack as customs DWG drawing and sample offer. Dorstener Wire Tech has over 15 years experience in manufacturing extruder screens and.

Extruder Screen The Ultimate Faq Guide Filson Filter

JELLIFF CORPORATION can supply a complete range of sizes and shapes of screens in steel and stainless steel.

. The Nordson Screen Pack is made of high-quality weaves combined to ensure the highest filtration efficiency. Our extruder screens are designed to optimize polymer flow distribution control and reduce the presence of gels adjust polymer residence time and increase flux and shear rates. Competitive price Extruder Screen Pack with spot welded or alloy border rim edgeused in plastic or rubber extrusion industry.

Clean by backwash at 2 to 5 volumetric throughput capacity. We are conveniently located in Paterson New Jersey. This screen is stronger and ensures a cleaner extrusion suitable for.

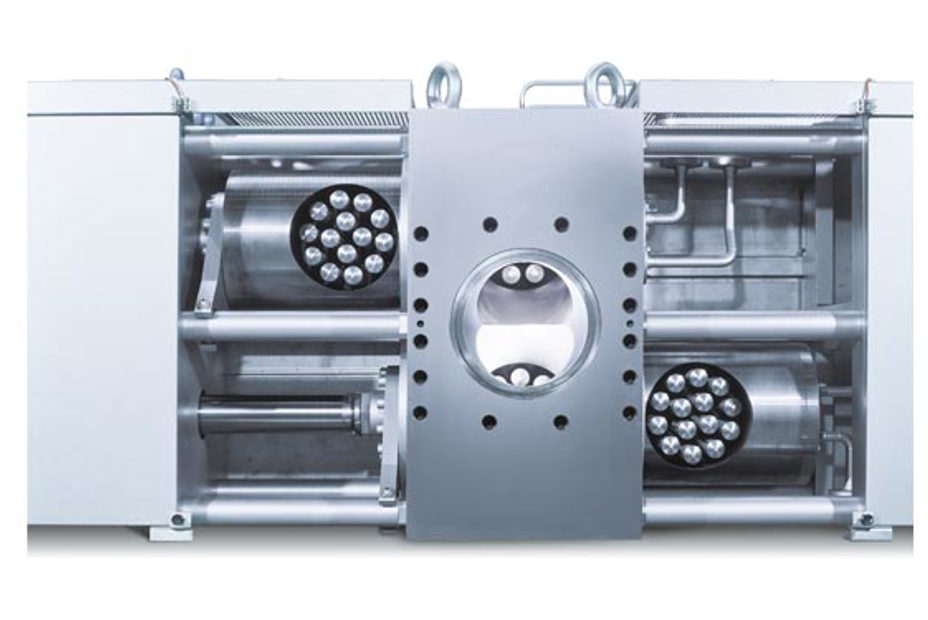

There is enormous technological. The Mixing Breaker Plate MBP is similar to the standard breaker plate in that it is stationary in the extruder can hold a screen pack and also reduces screw beat. Coperions SWZ screen pack changer ensures maximum productivity in the production of polyolefins.

As the screen. Extruder Screens Polymer Filters. Maximum productivity in the production of polyolefins.

However this new device is designed to created strong elongational flows for dispersive mixing by. Spot welded mesh screen in three layers. The shapes for have circle disc square oval rectangular ringkidneyTrapezoid cones other special shape and Customized For suitable to manchines types have For RSF series For SFX SF series For KF FF2 series with extrusion filter machine.

Square weave layers provide unique structural strength and ensure maximum stability against mechanical stress. Extruder Screen Mesh packs are mainly made from high quality SS 316 SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns and used for Plastic and Rubber Industry. And the screens are in a symmetrical fashion which prevents the screen pack from accidentally being installed.

Rotating microscreen batch fluid loading 3 to 6 Ls m of submerged area usually 66 area submerged solids loading 005 to 01 gs m headless 7 to 14 cm to max. We are a profile extruder with a 25 year history in manufacturing. Also available are spot-welded and aluminum bound screen packs.

It is designed especially for the melt filtration in high-performance compounding systems. Depending on the requirements of the material and the filtration grade the multi-layer extruder screen pack usually contains 2 to 5 layers. Stainless Steel Extruder Filter With.

The fine mesh Dutch Weave Wire Cloth Layer together with a Plain Weave Square Mesh support layer forms screen packs are used for. These extruder screen packs come in many forms of design sizes and types giving both wholesalers and retailers a wide range of choices. Screen pack downstream of extruders screen pack area.

Up to 5 years warranty. Layers from an optimized Dutch weave ensures maximum permeability. Multi-layer extruder screen pack is formed by cutting the screen into the required shape and size and then spot welding the screens.

Available in both single-layer and multi-layer configurations extruder screens remove impurities from melted plastic. We have been serving the POP industry both directly and as a secondary supplier to some well-known local firms. Extruder screen gives various shape options for you to customize and we will design every product carefully trying to match with all application requirements.

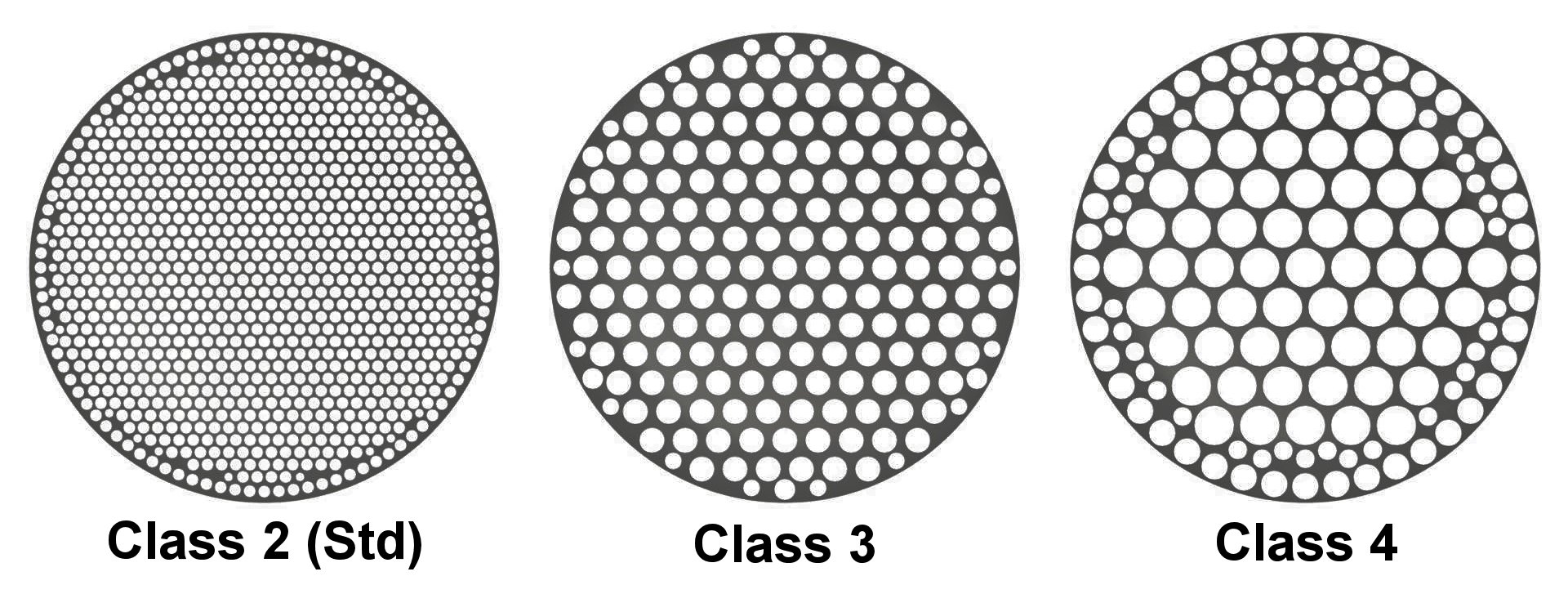

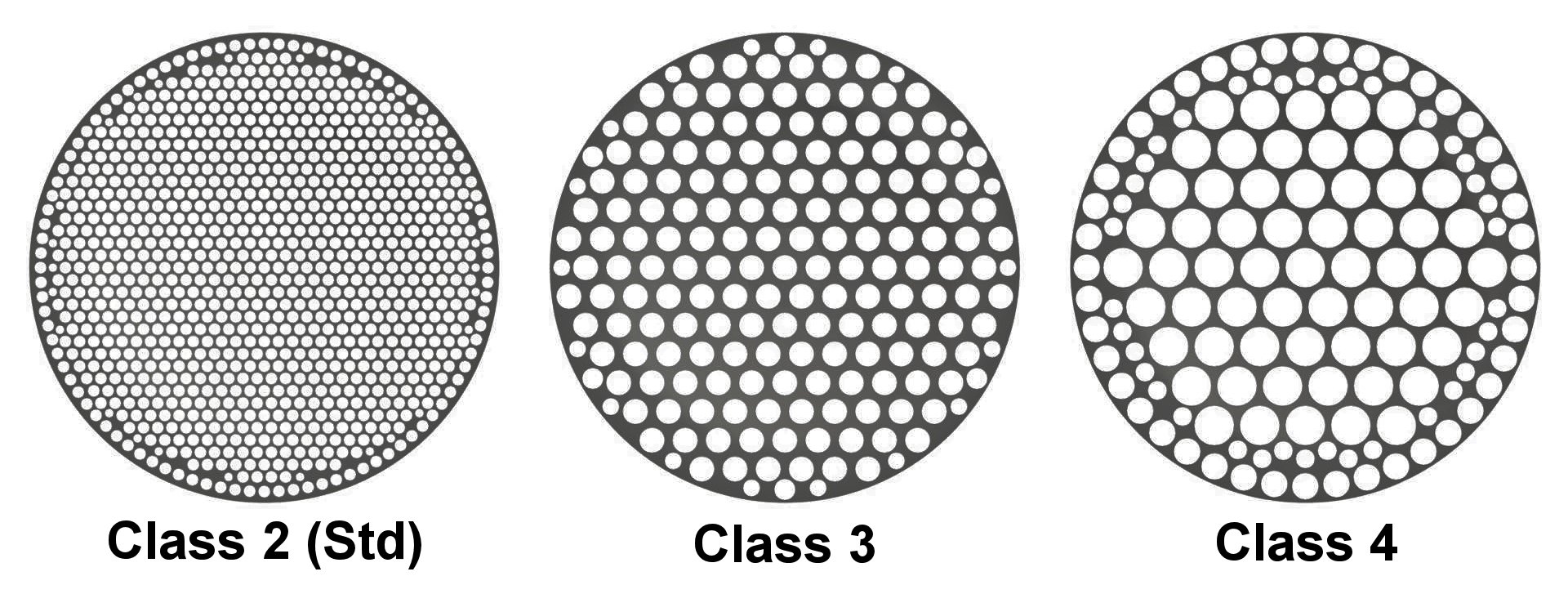

Cylindrical Extruder Screen Cylindrical extruder screen is widely applied in extrusion or filtration process in petrochemical pharmaceutical rubber and plastic industries. Screens are often put in as a screen pack with two three or more screens of different meshes. Extruder screen pack Extruder Screen pack Extrusion conditions Zone 1 Zone 2.

406080100 stainless steel mesh extruder pack. We would like to introduce you to All American Extrusion. This pack screen filter is designed to keep away mixing of foreign particles in finally equipped extrusion product.

Extruder screens and polymer filters are just two of the varieties of filtration products offered by Dorstener Wire. Hightop extruder screen pack can be produced by using different media such as woven wire mesh sintered fiber felt sintered wire mesh laminate to increase yield and quality and reduce process. We currently have 8 extrusion lines with 6 more coming on.

Samples for trial on extruders are provided. Take as an example a situation in which an operator is attempting to extend a production run between screen changes. Most packs have the coarsest screen up against the breaker plate to support the others but putting it in backward also works as the bigger particles get caught first and never reach the finest screen.

An extrusion screen doing its job. The screen packs can be changed during operation without interrupting or reducing the production. Extruder screen pack is durable and rigid useful in fine extrusion process for prevention impurities also useful for water treatment plant.

406080 stainless steel mesh extruder pack. Delivery to UK. Breaker plate is to support the screen pack and reduce screw beat.

Also called polymer filter or melt filter screen. Extruder Mesh Screen Welded Multi Layer Type. Changeovers are simplified and downtime is reduced because the design permits the extruder screw to be pulled through the screen changer.

Polymer and fiber processing requires a wide range of filters and filter media for processing finishing and recycling the materials. An extruder screen commonly referred to as a screen pack is a woven wire filtration system that is formed to meet the needs of the customer. Spot welded mesh screen in four layers.

In the different mesh size screens the finest wire screen is in the center of the pack and the larger mesh opening screen is successively placed outer sides. Nordson Screen Packs are tailored to the cavity and provide optimum. Utilize a screen-pack configuration fully optimized for their process.

In plastic extrusion stainless steel extruder screen is designed for PP PE and other plastic hot-melt extruding processes. Our fabricating facility located in Hickory North Carolina can fill your extruder screen requirements in a prompt and economical fashion. Multilayer extruder screen pack is made from several screens of different mesh sizes by welded them together.

Extruder Screen The Ultimate Faq Guide Filson Filter

Extruder Screen Packs Polymer Melt Filter Elements

China Extruder Screens And Screen Pack For Filtration And Plastic Extrusion Process China Extruder Screen Extruder Screen Pack

Bp Class Screen Changer Breaker Plate Psi Polymer Systems

0 comments

Post a Comment